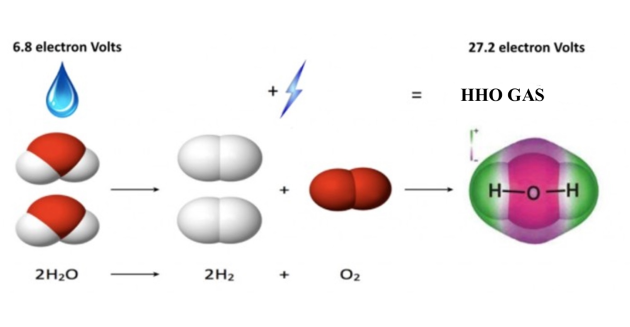

Oxy-hydrogen gas, or HHO (also known as Brown’s Gas), is a clean, high-energy fuel created by electrolyzing water into hydrogen and oxygen in a fixed ratio. First developed by Professor Yull Brown in 1976, HHO can be used alongside conventional fuels like coal, diesel, gas, or biomass to improve combustion efficiency and reduce emissions. It burns cleanly, and is produced using a small amount of electricity and water, forming a closed, renewable energy cycle.

In operational plants, HHO integration has delivered the following:

10–15% fuel savings

Visible reduction in smoke and particulate matter

Stable performance across long operational cycles

Compatibility with both small and large-capacity systems

Increased Fuel Efficiency

HHO enhances the combustion of the primary fuel, reducing the total fuel volume required. In some deployments, fuel efficiency improvements of up to 15% have been recorded.

Reduction in Emissions

Its implosive combustion properties help neutralize toxic gases, significantly reducing particulate matter, smoke, and other pollutants.

Cost Savings

As global fuel prices rise, reducing consumption translates directly to financial savings. For industrial plants with huge annual fuel spends, this can result in substantial savings.

Fuel Versatility

HHO gas works in combination with a wide variety of fuels such as coal, biomass, diesel, natural gas, syngas, LPG, CNG, and PNG, making it adaptable to existing systems across industries.

Non-toxic, Renewable, and Safe

Since HHO is generated from water, it is inherently renewable. The gas is produced on demand and consumed immediately, minimizing storage risks.

When injected through the air intake of industrial combustion systems, HHO accelerates flame propagation and increases combustion temperature. This allows the primary fuel to combust more completely, improving heat transfer and reducing unburnt residue.

- Fuel reduction in combustion equipments

- Efficiency enhancement in diesel engines

- Combustion support in boilers, furnaces, and thermic fluid heaters

- Replacement for oxy-acetylene or LPG in metal cutting